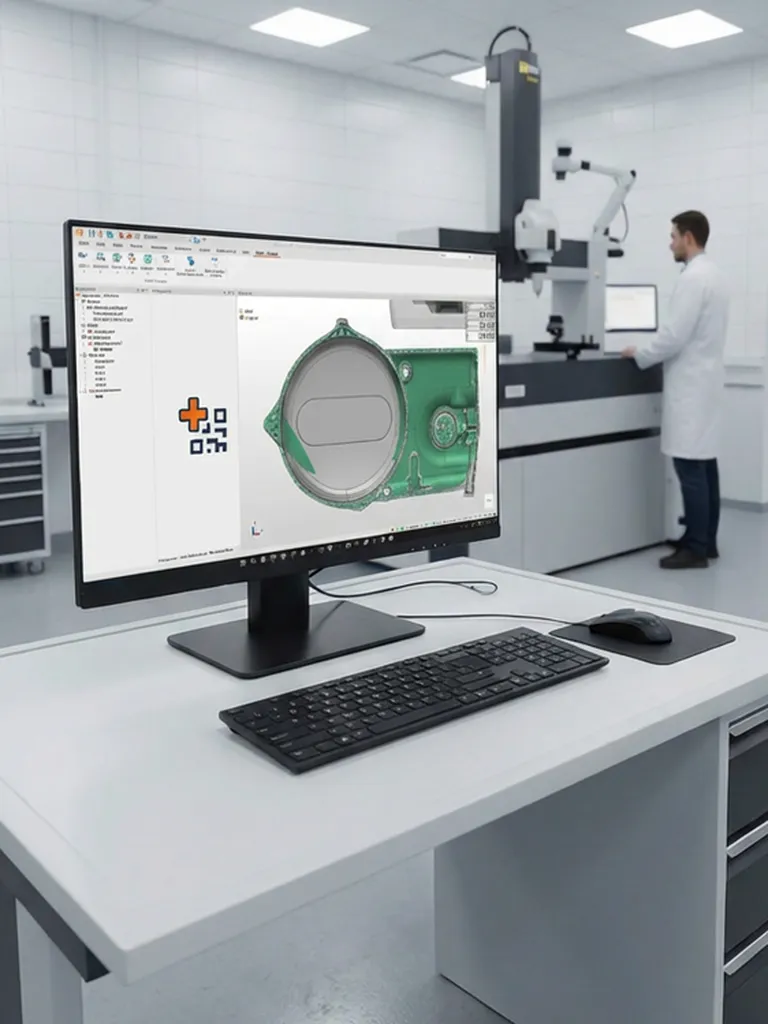

D3D++ Plug-In

More efficiency. More automation. More PolyWorks®.

The PolyWorks® Plug-In D3D++ is developed by Duwe-3d AG and ensures more efficient work and better business processes.

The Duwe-3d plug-in is the ideal extension for companies that want to seamlessly connect their processes with PolyWorks®. Developed from decades of experience in measurement technology, the plug-in connects data flows and creates the perfect bridge between powerful measurement software and the individual requirements of modern business processes. The D3D++ plug-in is available in two versions: D3D++ Standard and D3D++ Pro Automation.

Through intelligent integration, the plug-in not only increases the efficiency and transparency of your processes, but also makes PolyWorks® even more powerful, flexible, and future-proof.

This turns PolyWorks® not only into a powerful measurement tool, but also into a central building block for your digital process landscape.

We are a member of the OPC Foundation.

OPC UA is a data exchange standard for industrial communication that is independent of manufacturer, programming language and operating system. OPC UA can semantically describe machine data and make it accessible in vertical and horizontal directions. OPC UA is secure and reliable and enables interoperability between devices from different manufacturers.

The smart extension for PolyWorks|Inspector™

With the D3D++ Standard plug-in, you can expand your measurement software with powerful functions that make the entire inspection process more efficient, secure, and convenient. Whether importing inspection feature plans from leading OEMs, exporting inspection results in accordance with standards, additional measurement strategies, or automated initial sample inspection reports in accordance with VDA Volume 2—D3D++ Standard supports you in all key tasks in quality inspection. Supplemented by user-friendly toolbars, a versatile function library, and special CNC tools, the plug-in offers a practical solution for modern measurement technology requirements.

The plug-in includes the following features:

Import inspection feature plans from OEMs Audi, BMW, Daimler, Opel, and VW into PolyWorks|Inspector™. This feature allows inspection feature plans (e.g., from CAD models, ERP systems) to be transferred directly and automatically into the PolyWorks measurement software using the D3D++ plug-in.

Export your inspection results from PolyWorks|Inspector™ directly into the required formats of leading OEMs such as Audi, BMW, Daimler, Opel, and VW—quickly, securely, and in compliance with standards. In addition, independent export formats such as DMO (DMIS), Flex-Text, and DFQ are available for maximum compatibility with CAQ and ERP systems.

With D3D++ additional measurement methods for relative measurement, gap & flush, ball adapter and many more can be used in PolyWorks|Inspector™.

With D3D++ you can now automatically create a production process and product release according to VDA Volume 2.

D3D++ contains additional functions, toolbars and macros that are appreciated by many PolyWorks users.

Use D3D++ for an easy and safe

safe handling of your CNC measuring machine

Quick and easy access to frequently used functions of CNC measuring machines.

D3D++ supports you in dealing with scan paths and laser scanners on CNC measuring machines.

New measuring method for monitoring and documenting component and axis temperatures.

Password protects your CNC configuration from unauthorized or unwanted changes.

D3D++ offers the possibility to monitor, document and automate the measurement of the sensor system orientations in a measurement sequence.

The D3D CNC Setup and Servicing Toolbar supports you in setting up and monitoring CNC measuring machines.

Maximum flexibility through interfaces & automation

Take your quality processes to the next level with D3D++ Pro Automation: The software package includes all the functions of D3D++ Standard and expands them with powerful interfaces and automation solutions. Whether OPC UA for smooth data exchange, RoboDK for robot integration, web service and TCP/IP connections, or MQTT and serial interfaces—D3D++ Pro Automation connects your measurement technology with production and enables consistent, automated workflows. Supplemented by specialized toolkits for CNC and duplex applications as well as the MiR toolbar for mobile robotics, you can create a future-proof, networked measurement environment.

Automate your inspection processes now

Thanks to OPC UA, different measuring devices and systems in a production line can communicate in real time. This makes it possible, for example, to detect deviations or problems at an early stage.

With our D3D++ plugin for RoboDK, you can expand your PolyWorks range of functions. The RoboDK interface gives you access to an extensive library of over 1.000 robot arms. Watch the product video RoboDK Toolbar

D3D++ allows HTTP(S) connection to web services, web pages or services.

D3D++ gives you network access to PolyWorks macro commands, e.g. to connect robotics and PLC systems.

MQTT is a standard IoT protocol for connecting sensors and devices.

Via D3D++ a project specific and flexible integration of devices with a serial interface (RS232) e.g. of dial gauges or temperature sensors is possible.

Simplifies the operation of your duplex machine and enables complex duplex applications, such as iterative alignments as part of a customer project.

Enables complex applications such as iterative alignments within a customer project.

With the MiR Toolbar, you can move your metrological components, mounted on a Mobile Industrial Robots system, fully automatically through a PolyWorks measuring sequence to various positions.

What's New in D3D++ 2025

Toolbar Extensions

With the new “Create QR code” function, a PDF document with an integrated QR code can be created using the D3D++ toolbar, which contains important information such as a measurement sequence for the currently open PolyWorks|Inspector™ project. With the new D3D++ function “Read QR code”, for example, the project can be opened with a smartphone or QR code reader and the measurement can be started automatically.

With the new D3D++ function “Read QR code”, a PolyWorks|Inspector project can be easily opened and started via QR code scan. The corresponding QR code is generated directly via the D3D++ toolbar using the “Create QR code” function.

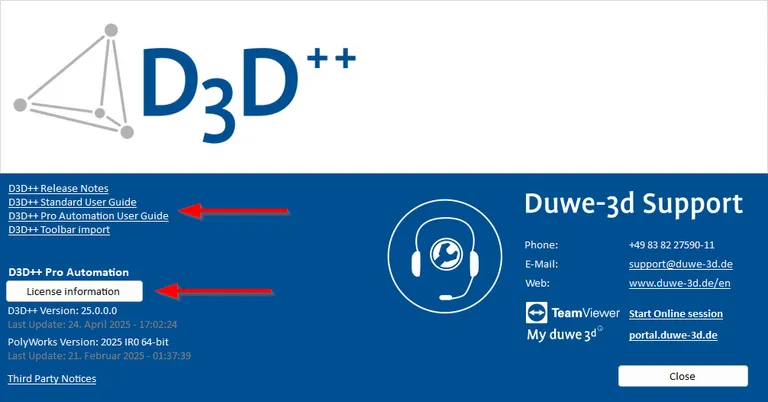

D3D++ plug-in activation and documentation

From D3D++ version 2025 IR0 an activation key is required to use D3D++. Please go to My Duwe 3d customer portal to get your activation key.

New documentation is available for D3D++ Standard and Pro Automation describing the features of each edition.

Read the knowledge article now

You want to know how to buy D3D++?

Please fill out the form. We will inform you about all further steps.

Release Information & Brochure

D3D++ Plug-In Brochure

Download (498.2 KB)Do you have any questions?